Table of Contents

Dizipal 554 has emerged as a versatile material with unique properties that cater to a wide range of industries.

In this article, we delve into the uses, benefits, manufacturing process, and future potential of Dizipal 554, shedding light on its significance in modern manufacturing.

What is Dizipal 554?

Dizipal 554 is a high-strength polymer renowned for its durability, resistance to chemicals and heat, and cost-effectiveness.

It finds applications in automotive, aerospace, medical, and industrial sectors where these properties are indispensable.

Composed of advanced synthetic compounds, Dizipal 554 has gained significant attention for its ability to withstand harsh environmental conditions and maintain structural integrity in diverse industrial settings.

Uses of Dizipal 554

Industrial Applications:

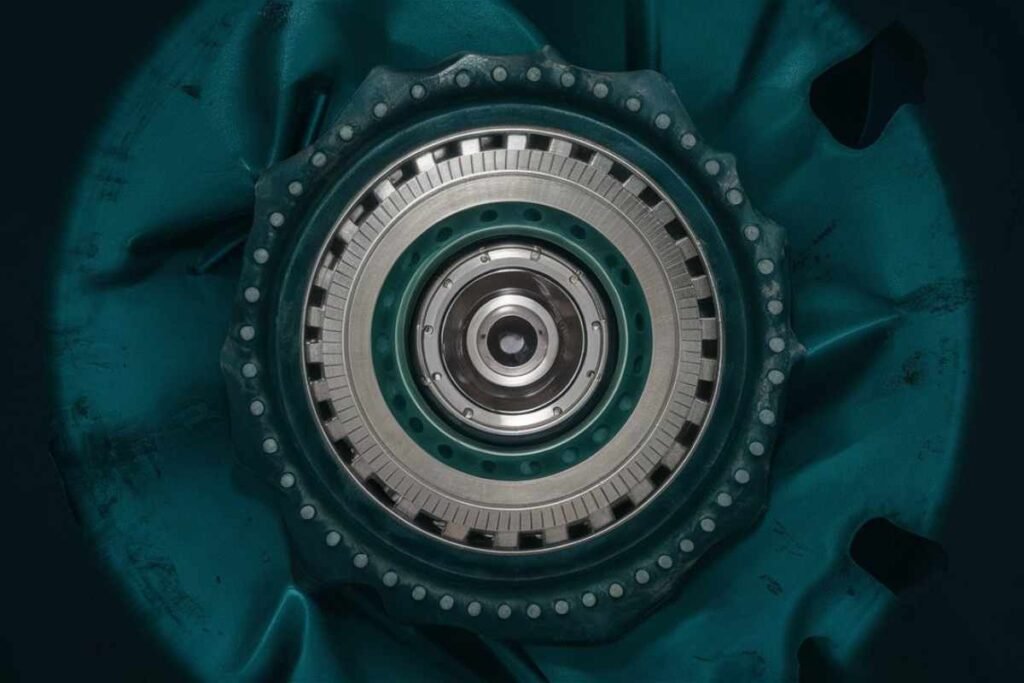

Dizipal 554 is utilized in industrial settings for manufacturing gears, bearings, and seals, thanks to its exceptional strength and durability.

Medical Applications:

In the medical field, Dizipal 554 is favored for surgical instruments, prosthetic devices, and medical implants due to its biocompatibility and corrosion resistance.

Benefits of Dizipal 554

Cost-Effectiveness:

Despite its high performance, Dizipal 554 remains cost-effective compared to alternatives, making it an attractive choice for various applications.

Durability:

Known for its longevity, Dizipal 554 ensures long-lasting performance, especially in demanding environments.

Environmental Impact:

Dizipal 554 is recyclable, reducing its environmental footprint and promoting sustainability compared to other materials.

Manufacturing Process

The manufacturing process of Dizipal 554 typically involves a method called polymerization.

During polymerization, monomers, which are the building blocks of polymers, are chemically bonded together to form the polymer chain of Dizipal 554.

The specific process may vary depending on the desired properties of the final product and the intended application.

Through careful control of temperature, pressure, and chemical additives, manufacturers can tailor.

The manufacturing process to achieve the desired characteristics such as strength, durability, and resistance to chemicals and heat in Dizipal 554

Polymerization:

The process begins with polymerization, where monomers, which are small molecules, undergo a chemical reaction to form polymer chains.

In the case of Dizipal 554, specialized monomers are selected to produce a polymer with specific properties such as high strength, durability, and resistance to chemicals and heat.

Monomer Selection:

The choice of monomers is crucial and depends on the desired characteristics of the final product.

Manufacturers carefully select monomers that will result in a polymer with the desired properties, such as strength, flexibility, and chemical resistance.

Reaction Conditions:

Polymerization typically occurs under controlled conditions of temperature, pressure, and catalysts.

These conditions are optimized to ensure the monomers react efficiently and form the desired polymer structure

Comparison with Other Materials

Dizipal 554 has a unique combination of high strength, low weight, and resistance to corrosion and chemicals that makes it a preferred choice in many situations when compared to materials like steel or aluminum.

Strength and Weight:

Dizipal 554 offers a remarkable strength-to-weight ratio, meaning it provides high strength while being lightweight.

This characteristic makes it advantageous for applications where weight reduction is critical without compromising structural integrity.

Resistance to Corrosion and Chemicals:

Unlike steel, which is prone to corrosion, and aluminum, which may react with certain chemicals, Dizipal 554 exhibits exceptional resistance to corrosion and chemicals.

This property ensures longevity and reliability in environments where exposure to corrosive substances is common.

Durability and Longevity:

Dizipal 554 is known for its durability and longevity, outperforming traditional materials like steel and aluminum in terms of wear resistance and lifespan.

Its resistance to degradation over time contributes to reduced maintenance costs and enhanced performance in various applications.

Future Potential of Dizipal 554

With ongoing research and development efforts, the future potential of Dizipal 554 is promising. Continued advancements aim to further enhance its properties and expand its applications across various industries.

Conclusion

In conclusion, Dizipal 554 stands as a formidable material with an array of remarkable properties that cater to diverse industrial needs.

Its versatility, durability, and resistance to harsh environmental conditions make it a preferred choice across industries such as automotive, aerospace, medical, and industrial manufacturing.

Moreover, its cost-effectiveness and recyclability underscore its sustainability, further cementing its position as a material of choice for the future.

With ongoing research and development endeavors aimed at enhancing its properties and expanding its applications, Dizipal 554 holds immense promise for revolutionizing modern manufacturing processes and pushing the boundaries of technological innovation in the years to come.

FAQs

What makes Dizipal 554 unique?

Dizipal 554 stands out for its high strength, durability, and resistance to chemicals and heat, making it ideal for demanding industrial environments.

What are the primary applications of Dizipal 554?

Dizipal 554 finds extensive use in industries such as automotive, aerospace, medical, and manufacturing for components like gears, bearings, surgical instruments, and prosthetic devices.

How does the manufacturing process of Dizipal 554 work?

Dizipal 554 is typically produced through polymerization, where specialized monomers are chemically bonded to form polymer chains under controlled conditions of temperature, pressure, and catalysts.

What advantages does Dizipal 554 offer over traditional materials?

Dizipal 554 boasts a superior strength-to-weight ratio, exceptional resistance to corrosion and chemicals, and longevity compared to materials like steel and aluminum.

Is Dizipal 554 environmentally friendly?

Yes, Dizipal 554 is recyclable, reducing its environmental impact and promoting sustainability in manufacturing processes.

What does the future hold for Dizipal 554?

Ongoing research and development efforts aim to further enhance the properties of Dizipal 554, expanding its applications and solidifying its position as a key material for future technological innovations.